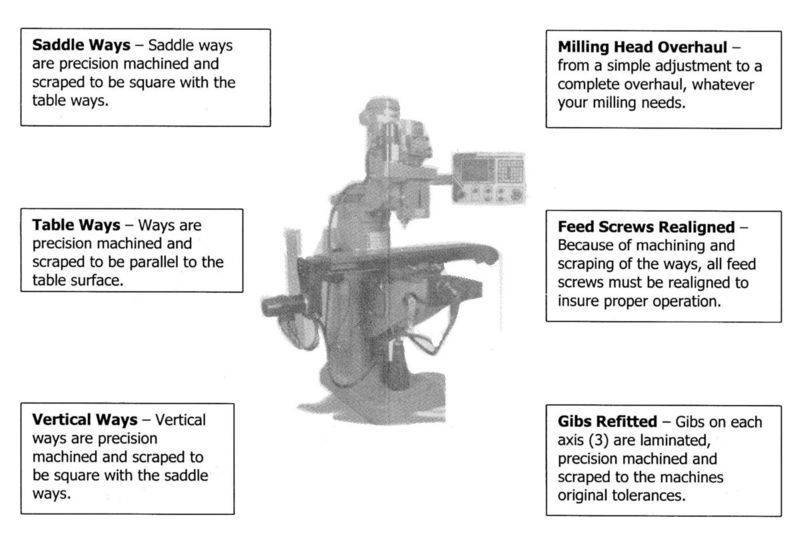

Rebuild Your Worn Machine ToolsMost machine tools don't simply stop operating when worn, if they did, deciding to either replace them with a new machine or rebuild them would be easy to do. Instead, a machine slowly loses tolerance and begins to log increasing amounts of downtime and maintenance costs. Machines in this condition are still serviceable and can be rebuilt to bring back the original specification at a fraction of the cost of a new machine. Rebuilding can be done in as little as 2 to 3 weeks, while you could wait up to 12 months for delivery of a new machine. Our facilities are geared specifically to rebuilding Machine Tools in order to keep costs down and delivery time to a minimum.

Your plant or ours - Service Calls AvailableCall 715-749-3065 today!Accessories, Repairs and Other Available Optional FeaturesChrome Plated WaysTo maintain as far as possible the inherent accuracy and sensitivity of machine tools, the exclusive feature of chrome plated ways is longer life to your machine. For a modest cost we can Chrome Plate Ways at points of maximum wear. One Shot Lube SystemA new one shot lube system can be installed to assure protection of the critical surface areas that were scraped during rebuilding. Milling HeadFrom minor adjustments to a complete overhaul can be made on any model. All parts are stocked so no long waiting periods will be involved. PaintingYour rebuilt machine can be painted to protect it from rust and corrosion and to make it look like new. |